Valve Lines

BOC Components, Inc.

offers custom designed and engineered products. We offer top of the line BOC products, but we also service other manufactures as well. We are confident in our work, which is why all of our products are tracked for performance and reliability by RDN (Reliability Data Network).

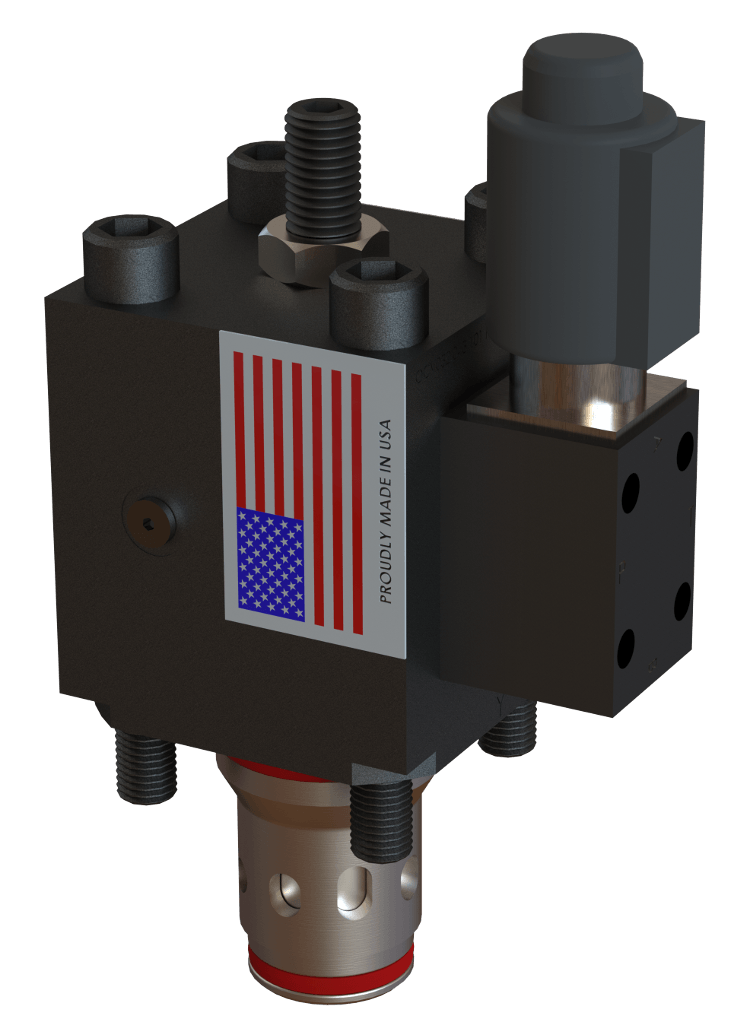

Descale Valves

- Rugged construction for the harshest descaling environments

- Quad-S Cutting Water Cartridge Technology

- V010 Pilot Control System

- Bolt in replacement for all cutting water isolation valves

- Both the DS Cartridge Style and RP Radially Ported Style are available

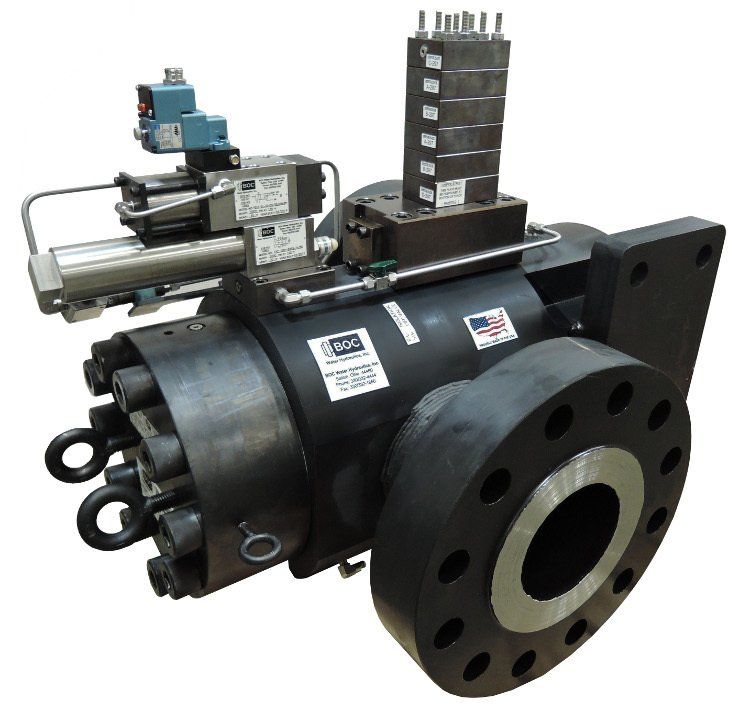

Decoking Valves

- Direct replacement for all 90 & 180 degree flanged envelope decoking valve

- Quad-S Cutting Water Cartridge Technology

- PTC (Pump Thrust Control) eliminates jet pump rotor position excursion

- V010 Pilot Control System provides redundant protection from pump dead head conditions

Directional Control Valves

- Designed specifically for Mill Duty applications

- NFPA & MSA patterns supported

- Flexible and durable utilizing the BOC Quad-S Cartridge

- Designed for drop-in replacement of valves currently in place

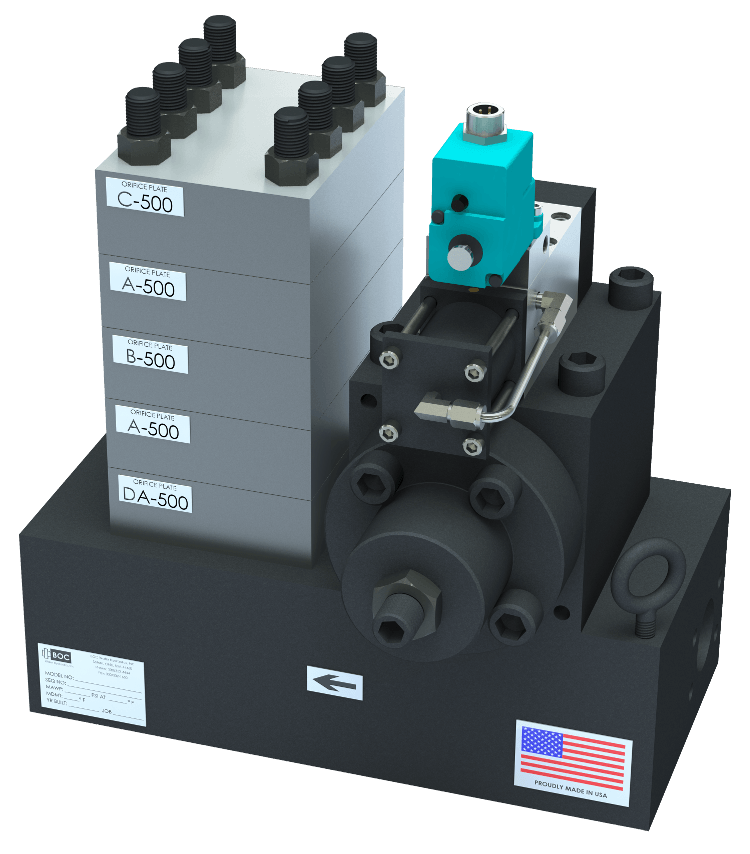

Pump Bypass Units

- Provides control and reliability for successful operation of pumps

- Protects the pump when in bypass mode

- Consists of a Main Valve, Pilot Valve, and Pressure Reducing Orifice Stack

- Sizes ranging from Din 16 through Din 200

- Many different styles available based on your specific application

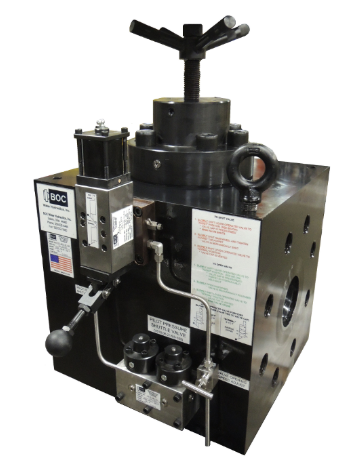

Hydraulic Assisted Stop Valves

- Hydraulic assist controls opening and closing of valve with the push/pull of a lever

- Once the valve is in position it can be mechanically locked into place in either position

- Energy to open and close the valve comes from the fluid media in the valve

- Rugged construction that can take the abuse of a demanding application (high dirt, high pressure)

Oil Cartridge Valves

- Full Repairs

- Parts Availability

- Site Service

- Total Replacements

- Conforms to ISO 7368 standards

- Interchangeable with all ISO 7368 cavities, including Oilgear, Eaton/Vickers, etc.

Low Pressure Valves

- Typically operated with 150 psi, but options are available to support pressures as low as 40 psi

- Available in 4", 6", 8", and 10" sizes

- Variety of mounting options available for 150#, 300#, and 600# rated flanges

- Valves are adaptable to meet any existing mounting envelope

- Long operational life even withstanding the harshest of operating environments

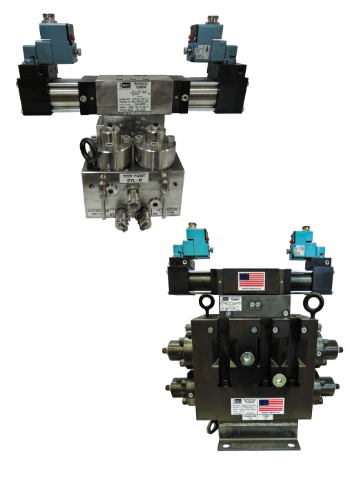

Pneumatic (Air) Valves

- Full-flow spool-packed valves that can meet any control requirement

- Designed for use with air, water or hydraulic fluids with pressures up to 300 psi and temperatures up to 150° F.

- Available in 2-Way, 3-Way, and 4-Way operations

- Numerous solenoid valve types and actuator options available

- U-Cup packing for durability in high dirt environments

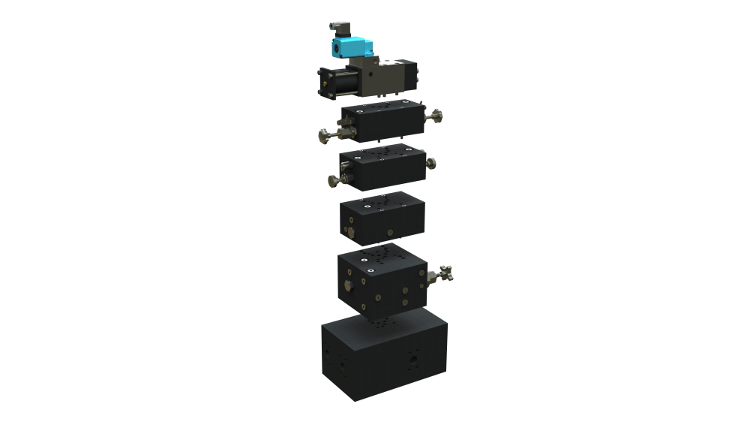

Mod Stacks

- Stacked components that are 100% customized for any application

- Components can be stacked in any order, based on need and preference

- Components can include Pilot Valves, Shut Offs, Flow Controls, Check Valves, Pressure Reducing Orifices, and much more

- All stainless steel construction for durability and reliability

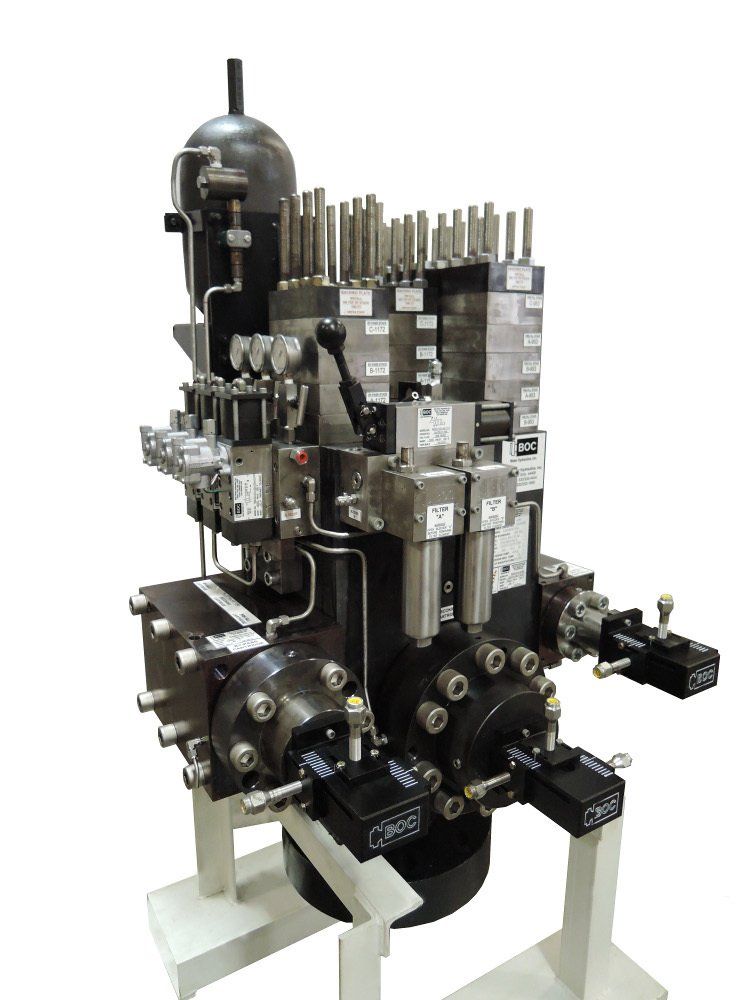

Valve Stands

- Ease of Service: utilizing BOC’s cartridge technology, servicing can be done quickly, in-place and at bench height

- Ease of Troubleshooting: valve stands come with test ports installed on pressure cavities and pilot lines. Optional gauge boards facilitate real time troubleshooting

- Eliminate External Leaks: changing out valves only eliminates part of the problem, often costly nagging piping leaks remain; manifold mounting provides tight fluid interfaces. A single P&T line reduces piping and leak points

- Flexible Packaging: porting can be located on the top, bottom, or rear to meet your piping requirements

- Simple Installation: stand is built complete and tested end-to-end, ready to set in place